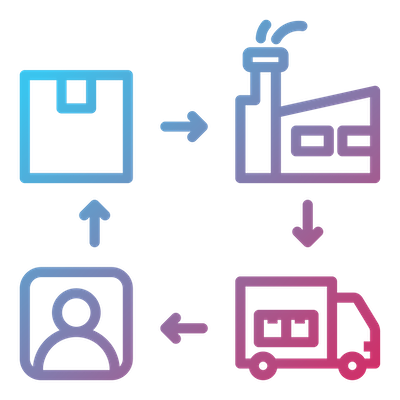

AI-Powered Supply Chain & Inventory Optimisation

Harness advanced AI Supply Chain Optimisation to forecast demand with precision, maintain ideal inventory levels, and streamline supply chain processes for maximum efficiency and business growth.

Overview

Modern supply chains operate in an environment of constant change, where balancing stock levels and meeting demand can be challenging. Overstocking ties up capital and creates storage issues, while stockouts lead to lost sales and unhappy customers. GullyAI's AI Supply Chain Optimisation and AI Inventory Management solutions use AI Demand Forecasting models to analyse sales history, seasonal patterns, market trends, and real-time logistics data.

Our models forecast demand with exceptional accuracy, optimise inventory placement, and automate replenishment to improve operational efficiency, reduce costs, and boost profitability across the entire supply chain.

Benefits

Reduced Stockouts & Overstocks

Prevent costly supply chain imbalances by using AI Supply Chain Optimisation and AI Demand Forecasting to align stock levels with real customer needs across all locations

Improved Cash Flow

Maintain optimal inventory turnover so working capital is freed up for growth initiatives while ensuring customers receive products on time, every time

Higher Forecast Accuracy

Achieve more reliable demand predictions by combining historical sales, market signals, and external data such as weather and economic indicators

Operational Efficiency

Streamline warehouse, procurement, and logistics processes with AI-driven automation, reducing manual errors and eliminating bottlenecks in the workflow

Sustainability Gains

Support environmental goals by reducing overproduction, minimising product waste, and lowering the carbon footprint of your supply chain operations.

Services

AI Demand Forecasting ModelsGenerate accurate demand predictions that adapt to changes in trends, seasonality, and market conditions, enabling proactive AI Supply Chain Optimisation

Inventory Optimisation Solutions

Determine optimal stock levels for each location by factoring in lead times, safety stock, sales velocity, and storage capacity constraints with AI Inventory Management

Supply Chain Visibility Dashboards

Gain real-time insight into inventory positions, supplier performance, and demand trends to make fast, informed operational decisions

Automated Replenishment Systems

Deploy AI triggers that initiate purchase orders automatically when predicted demand and stock thresholds indicate restocking is required

Scenario Planning & Risk Management

Use AI simulations to test strategies for potential disruptions, ensuring supply chain resilience under various business conditions.

Use Cases

Retail Chains

Ensure stores have the right stock mix at the right time to prevent lost sales while avoiding excess inventory and unnecessary carrying costs

FMCG Brands

Balance production schedules and distribution networks to meet fluctuating consumer demand while optimising storage and transportation resources

Logistics Providers

Improve routing, load planning, and delivery schedules using predictive analytics to enhance service quality and reduce operational expenses

E-commerce Platforms

Keep fulfilment centres stocked with in-demand products, enabling fast shipping times and consistently high customer satisfaction rates

ManufacturersAlign production capacity with forecasted demand to minimise idle resources, avoid delays, and optimise the use of raw materials.

Why Choose Us

Proven Industry Expertise

We have successfully delivered AI Supply Chain Optimisation solutions for retail, manufacturing, FMCG, and logistics leaders worldwide

Advanced Predictive Accuracy

Our AI Demand Forecasting models use hundreds of data points, providing superior forecast precision compared to traditional demand planning methods

Seamless Platform Integration

We integrate with ERP, WMS, and SCM platforms to ensure smooth adoption without disrupting existing business operations

Scalable for Future Growth

Our AI solutions adapt to new products, markets, and business models, ensuring long-term value as your operations expand

Continuous Model Optimisation AI systems learn from new data and adjust predictions over time, maintaining peak performance in dynamic market conditions.

Frequently Asked Questions

Your AI Transformation Starts Now

Whether you're starting small or aiming for enterprise-wide adoption, GullyAI delivers AI Solutions that make measurable business impact.

Book a Free Consultation